The Crucial Role of Friction in Braking Systems

Friction plays a vital role in the function of a vehicle’s braking system, as it’s the force responsible for slowing and stopping a car. By understanding the science behind friction, we can better appreciate the importance of proper brake maintenance and the choice of high-quality components for optimal braking performance and vehicle safety.

Friction Explained: The Basic Physics Behind It

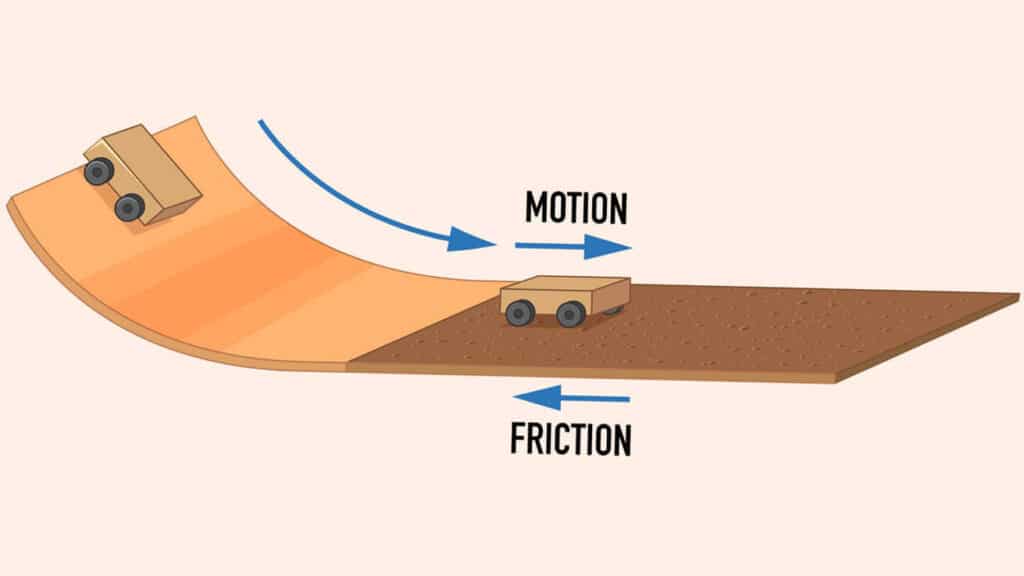

Friction is the force that resists the motion of two surfaces in contact with each other. In the case of braking systems, friction is generated when brake pads or shoes press against the rotors or drums, causing the vehicle to slow down or come to a stop. The greater the friction, the more effective the braking force.

The Components of a Braking System: Where Friction Comes into Play

Brake Pads and Rotors in Disc Brakes

Disc brakes, which are commonly found on modern vehicles, consist of two main components: brake pads and rotors. The brake pads are made of a friction material that is designed to generate the necessary stopping power when pressed against the rotors. The rotors are metal discs that are attached to the wheel hub, rotating along with the wheels. When the brake pedal is pressed, the brake calipers force the brake pads to clamp onto the rotors. This contact between the pads and rotors generates friction, which in turn converts the vehicle’s kinetic energy into heat. As a result, the vehicle slows down or comes to a complete stop, depending on the force applied to the brake pedal. Proper maintenance of brake pads and rotors, such as regular inspection and timely replacement, is essential for ensuring consistent and effective braking performance.

Brake Shoes and Drums in Drum Brakes

Drum brakes, often found on older vehicles or rear brakes of some cars, consist of brake shoes and drums as their primary components. The brake shoes are made of a friction material similar to brake pads and are shaped to fit the curvature of the drum’s inner surface. The drum is a metal cylinder that is connected to the wheel hub, rotating along with the wheels. When the brake pedal is pressed, the wheel cylinders push the brake shoes outward against the inner surface of the drum. This contact between the shoes and the drum creates friction, which slows the vehicle down or brings it to a stop. Drum brakes require regular maintenance, such as inspection and adjustment, to ensure optimal braking performance and prevent uneven wear or other issues that may compromise vehicle safety.

Brake Materials: How They Affect Friction and Braking Performance

Organic Brake Pads

Organic brake pads are made from a combination of materials such as rubber, glass, various fibers, and other resins. These pads are popular for their relatively low cost, quiet operation, and smooth braking feel. Organic brake pads are generally gentle on brake rotors, prolonging their lifespan. However, they may wear down faster than other types of brake pads and generate more brake dust. Additionally, organic brake pads may not perform as well in high-temperature situations, as they have a lower heat resistance compared to semi-metallic and ceramic pads. Despite their drawbacks, organic brake pads are a suitable choice for everyday driving and light-duty applications.

Semi-Metallic Brake Pads

Semi-metallic brake pads are composed of metal fibers, such as steel, copper, or brass, mixed with other materials to provide structure and support. These pads have a higher friction coefficient and are more effective at dissipating heat, which makes them suitable for more demanding driving conditions and high-performance applications. However, semi-metallic pads can be noisy due to their metallic composition and may wear down rotors faster than other pad types. Additionally, their performance may be somewhat diminished in extremely cold temperatures. Despite these drawbacks, semi-metallic brake pads are a popular choice for drivers seeking improved braking performance and heat management.

Ceramic Brake Pads

Ceramic brake pads are made from a blend of ceramic fibers, filler materials, and sometimes small amounts of metal. These pads offer several advantages, including consistent braking performance across a wide range of temperatures, minimal noise, and low brake dust generation. Ceramic brake pads also have a longer lifespan than organic pads and are gentler on rotors than semi-metallic pads. However, ceramic brake pads tend to be more expensive than other types of brake pads, making them a less budget-friendly option. Despite their higher cost, ceramic brake pads are an excellent choice for drivers seeking a balance of performance, noise reduction, and cleanliness in their braking system.

Heat Dissipation: Managing the Effects of Friction on Your Braking System

Brake Fade: The Consequence of Overheated Brakes

Proper heat dissipation is vital for maintaining the performance and longevity of your vehicle’s braking system. When brakes are applied, the friction generated between the brake pads or shoes and the rotors or drums converts the vehicle’s kinetic energy into heat. This heat must be managed and dissipated effectively to prevent brake fade, a condition that occurs when brakes overheat and lose their ability to slow down the vehicle effectively. Brake fade can lead to decreased stopping power, increased stopping distances, and in extreme cases, total brake failure. To manage heat dissipation, brake components such as rotors and drums are designed with ventilation features that help dissipate heat during use. Additionally, the choice of brake pad materials can significantly impact the heat management capabilities of the braking system. For example, semi-metallic and ceramic brake pads tend to offer better heat dissipation properties than organic brake pads. Regular maintenance, such as inspecting and replacing worn brake components, ensures that the braking system remains effective and efficient in managing the heat generated by friction during braking.

Maximizing Brake Performance: Choosing the Right Brake Components

Selecting the appropriate combination of brake components, including pads and rotors, is essential for maximizing friction and braking performance. When choosing brake materials, take into account factors such as driving conditions, vehicle type, and personal preferences to ensure the most effective braking experience.

Brake System Maintenance: Ensuring Optimal Friction and Performance

To maintain optimal friction and braking performance, it’s crucial to perform regular brake system maintenance. This includes inspecting and replacing worn components as needed. Adhering to manufacturer-recommended maintenance schedules can help ensure the best results, keeping your braking system in top condition and promoting a safer driving experience.

The bottom line

A deeper understanding of the role of friction in a vehicle’s braking system can lead to better decisions regarding brake component selection and maintenance. By prioritizing brake system care, you can ensure a safer and more reliable driving experience.