Introduction: The Unique Challenges of Heavy-Duty Fleet Vehicle Brake Systems

Heavy-duty fleet vehicles face unique challenges in maintaining their brake systems’ health and performance. These vehicles often carry heavy loads, operate in demanding environments, and are subject to strict regulations. As a result, fleet managers must prioritize brake system health to ensure safety, efficiency, and compliance. This article will explore the unique considerations of heavy-duty fleet vehicle brake systems and offer tips for proper maintenance and management.

Increased Weight: How Load Affects Brake Performance and Wear

Heavy-duty fleet vehicles typically carry much heavier loads than their lighter counterparts. The increased weight puts additional strain on the brake system, accelerating wear and potentially affecting braking performance. To counteract this, fleet managers must ensure that their vehicles’ brake systems are designed and maintained to handle the increased load, with regular inspections and timely component replacements.

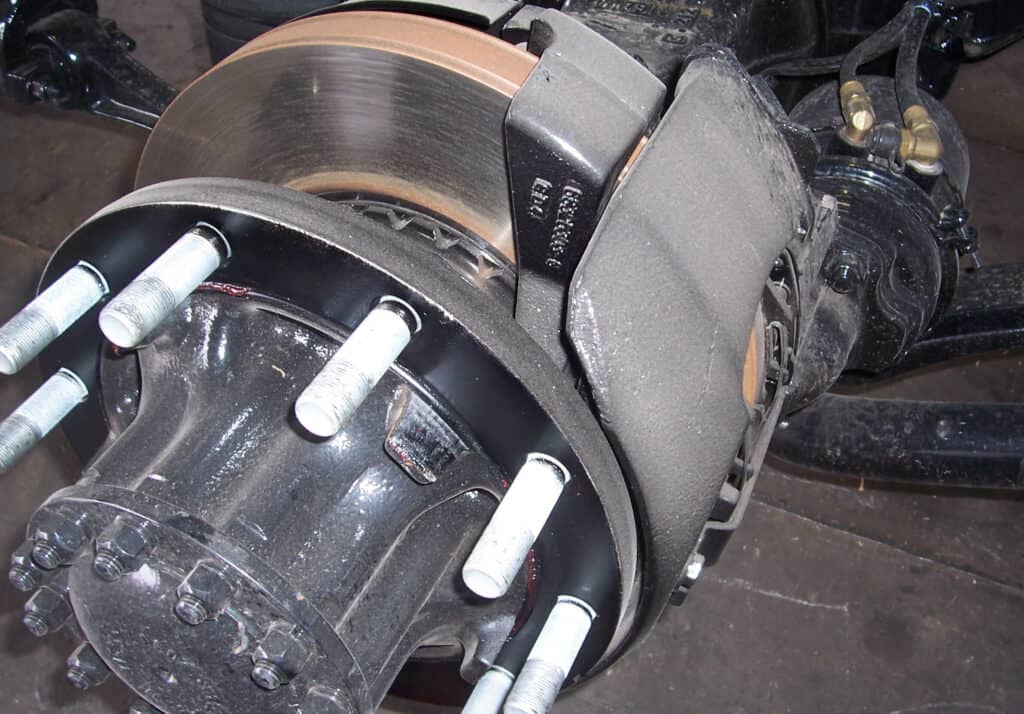

Brake Component Sizing: Selecting the Right Brakes for Heavy-Duty Applications

Selecting the right brake components for heavy-duty vehicles is crucial to ensure optimal performance and longevity. Larger, more robust brake components are often necessary to handle the increased weight and demands of heavy-duty applications. Fleet managers must carefully consider factors such as vehicle weight, load capacity, and operating conditions when choosing brake components for their fleet.

Air Brake Systems: An Overview and Their Advantages for Heavy-Duty Vehicles

Air brake systems are commonly used in heavy-duty fleet vehicles due to their superior performance and reliability under heavy loads. These systems use compressed air to apply pressure to the brake pads or shoes, providing consistent stopping power even under demanding conditions. Air brake systems also offer the advantage of simpler maintenance, as they require fewer components than hydraulic systems.

Hydraulic Brake Systems: When and Why They May Be Used in Heavy-Duty Applications

While air brake systems are the norm for most heavy-duty vehicles, there are situations where hydraulic brake systems may be used. These systems use hydraulic fluid to transmit force from the brake pedal to the brake pads or shoes. Hydraulic brake systems can provide smoother, more responsive braking, but may require more frequent maintenance and are generally less suitable for very heavy loads.

Brake Cooling: Managing Heat Dissipation for Optimal Performance

Brake cooling is a critical consideration for heavy-duty fleet vehicles, as excessive heat can lead to reduced performance, accelerated wear, and even brake failure. Fleet managers must ensure their vehicles are equipped with adequate cooling systems, such as vented rotors and cooling ducts, to dissipate heat effectively during heavy use. Regular inspections and maintenance can help to identify and address any cooling issues before they become problematic.

Brake System Inspections: Adhering to Strict Guidelines and Schedules

Heavy-duty fleet vehicles are subject to strict inspection guidelines and schedules to ensure their brake systems remain in good working order. Fleet managers must be diligent in following these schedules and adhering to inspection requirements, including visual inspections, performance tests, and component measurements. Failure to meet these guidelines can result in fines, penalties, and even vehicle impoundment.

Proper Maintenance: Preventing Downtime and Ensuring Compliance

Regular maintenance is essential to keep heavy-duty fleet vehicle brake systems in optimal condition, preventing downtime and ensuring compliance with regulations. This includes timely replacement of worn components, proper lubrication of moving parts, and addressing any identified issues during inspections. Fleet managers should establish a comprehensive preventative maintenance plan to keep their vehicles on the road and in compliance with industry standards.

Driver Training: Educating Heavy-Duty Fleet Operators on Brake System Health

Fleet operators play a critical role in maintaining the health of their vehicles’ brake systems. Providing comprehensive driver training on brake system operation, maintenance, and best practices can help to reduce wear, prevent accidents, and promote overall fleet safety. Drivers should be familiar with their vehicles’ specific brake systems, the warning signs of potential issues, and the appropriate actions to take in the event of a brake system problem. Ongoing training and refreshers can help keep drivers up-to-date and aware of their responsibilities.

Upgrading Brake Components: When and Why to Consider Enhanced Systems

There may be situations where upgrading brake components can be beneficial for heavy-duty fleet vehicles. This could include installing high-performance brake pads, rotors, or calipers designed for heavy-duty use or harsh operating conditions. Upgrading brake components can improve performance, reduce maintenance requirements, and extend the lifespan of the brake system. Fleet managers should carefully weigh the benefits and costs of these upgrades to determine if they are a worthwhile investment for their specific fleet.

Balancing Performance and Cost: Optimizing Brake System Health for Heavy-Duty Fleets

Maintaining the brake system health of a heavy-duty fleet involves balancing performance, safety, and cost considerations. While investing in high-quality brake components and regular maintenance can lead to higher upfront costs, these investments can pay off in the long run by reducing downtime, extending component lifespans, and ensuring fleet safety and compliance. Fleet managers should prioritize brake system health as a key component of their overall fleet management strategy.

Conclusion: Prioritize Brake System Health for a Safe and Efficient Heavy-Duty Fleet

Brake system health is of paramount importance for heavy-duty fleet vehicles, given the unique challenges they face in terms of load, performance, and regulatory requirements. By understanding these challenges and implementing proper maintenance practices, fleet managers can ensure their vehicles remain safe, efficient, and compliant with industry standards. Prioritizing brake system health is essential for the long-term success of any heavy-duty fleet.