Wheel bearings are an integral part of your vehicle’s structure. They enable your wheels to spin freely, contributing to a smooth ride, and they bear the load of the vehicle, making it safe to drive. But as sturdy as they are, they’re not impervious to the forces of nature. The Canadian weather, renowned for its extremities, can significantly impact the performance of your wheel bearings. In this article, we’ll delve into the climatic influences on your wheel bearings, and what you can do to ensure their longevity.

Weather and Wheel Bearings: The Connection Weather and wheel bearings have a significant relationship. Rain, snow, or road salt can accelerate corrosion and damage the seals, allowing water and dirt to enter the bearing. This can lead to premature wear and can reduce the bearing’s life significantly. Living in regions with such weather conditions, like Canada, calls for regular inspections and proper maintenance of your wheel bearings to mitigate these effects.

Temperature and Bearings: Temperature changes and the associated stress it places on wheel bearings are undeniable. The typical operating range for wheel bearings falls between 75°C and 120°C under regular driving conditions. However, as the mercury dips and rises, particularly in a country known for its temperature extremities like Canada, this range can be affected. The bearing metal expands and contracts with the temperature fluctuations, potentially causing structural changes or even damage. Particularly during the frigid Canadian winters, the cold-start wear and tear could be significantly higher.

Moreover, under strenuous driving conditions, or if there’s a bearing failure in progress, the temperature can escalate quickly, surpassing 150°C. This excessive heat can degrade the lubricant, compromising the bearing’s smooth operation and can lead to premature failure. Overheating often accompanies other symptoms of a failing bearing, such as noise and vibration. By keeping a vigilant eye on these indicators and ensuring preventive maintenance, vehicle owners can circumvent these risks, safeguarding their wheel bearings against extreme temperatures, and in turn, extending their longevity and performance.

The Dangers of Neglect: In the harsh weather conditions of certain regions, neglecting your wheel bearings can have dangerous consequences. One of the leading culprits of wheel bearing failure is overheating, which can be caused by a number of factors. Overloading the vehicle, using inadequate or deteriorated lubrication, or bearing damage from debris, water, or road salt are all conditions that can lead to overheating. The extreme temperatures of overheated wheel bearings can cause the metal to warp, leading to premature failure and increased risk of accidents.

Driving in extreme weather conditions like heavy snow or rain can exacerbate these issues. For instance, water and debris from the road can penetrate the wheel bearings, causing them to corrode or seize up. Salt used for de-icing roads can accelerate rust formation and lead to bearing failure. It is therefore imperative to pay special attention to wheel bearing maintenance in harsh climates. Regular inspections, correct loading, and proper lubrication can help maintain the integrity of the wheel bearings, ensuring your safety on the road, and avoiding costly repair or replacement in the future.

Lubrication and Bearings: Balancing lubrication for wheel bearings is crucial, especially in regions characterized by extreme weather conditions. Lack of lubrication can escalate friction, leading to overheating and eventually, bearing failure. On the other hand, over-lubrication isn’t beneficial either. Excess lubricant can create what’s known as fluid friction, leading to heat generation that can potentially damage the seals. In colder climates, such as those frequently experienced in Canada, this becomes even more critical, as temperature fluctuations can influence the performance of the lubricant, potentially causing it to become too thick or too thin.

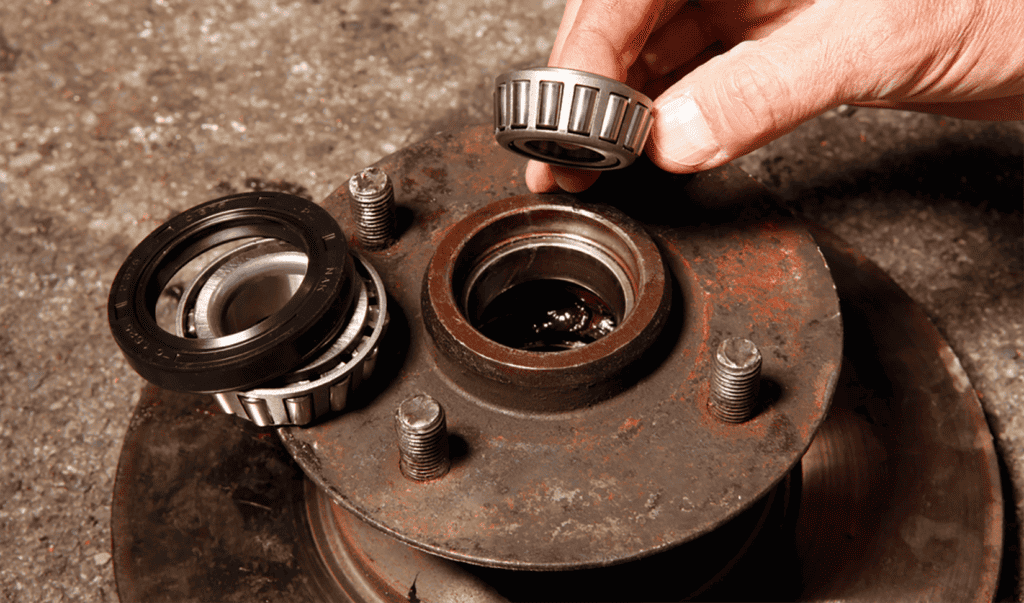

Choosing the right lubricant also plays a significant role in maintaining wheel bearing health. Typically, grease is preferred for wheel bearings because of its exceptional stay-in-place attributes and its resistance to water – a critical feature for regions known for heavy snowfall or rain. For high-speed applications, oil might be a more suitable choice, as it can provide more efficient lubrication. As for WD40, despite its usefulness in various applications, it’s not recommended for wheel bearings. It may dissolve the existing lubricant, and unlike grease or oil, it does not provide the long-term protection that wheel bearings require. In extreme weather conditions, opting for a lubricant specifically designed to withstand such conditions will ensure the longevity and efficiency of your wheel bearings.

Maintenance and Longevity: Living in an extreme weather region can present challenges to the maintenance and longevity of your wheel bearings. The combination of heavy snow, freezing temperatures, and salt on the roads, for instance, can accelerate corrosion and wear. Therefore, meticulous and regular maintenance is crucial in these conditions. Typically, it’s recommended to have your wheel bearings inspected and greased every 30,000 to 40,000 kilometers, though this frequency might need to be increased if you regularly drive in harsh conditions. Regular maintenance includes greasing your wheel bearings to ensure they stay lubricated, which reduces friction and wear.

The frequency of maintenance can also depend on your vehicle manufacturer’s guidelines, so it’s always wise to consult your owner’s manual or a trusted mechanic for personalized advice. Timely inspections can help detect early signs of wear or damage and can prevent small issues from escalating into more serious problems, saving you costly repairs in the future. In extreme weather conditions, a little vigilance goes a long way. Making wheel bearing maintenance a part of your vehicle’s routine care can extend its lifespan and ensure your safety on the road.

In conclusion, the climatic influences on wheel bearings can’t be ignored, especially in weather-extreme regions like Canada. Understanding the impacts and implementing regular maintenance can go a long way in ensuring the longevity and optimal performance of your wheel bearings. Always remember that while the weather might be out of your control, taking care of your wheel bearings is within your grasp.